Laser-welding

POWER WELDING LASER MACHINE

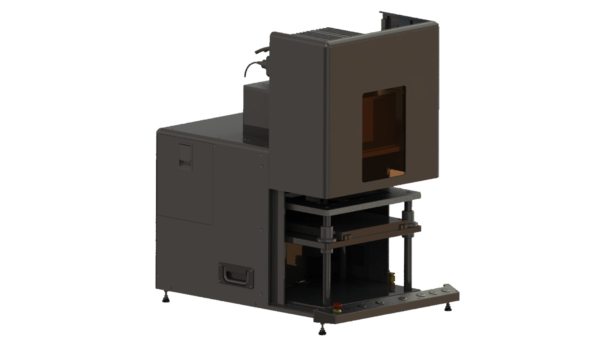

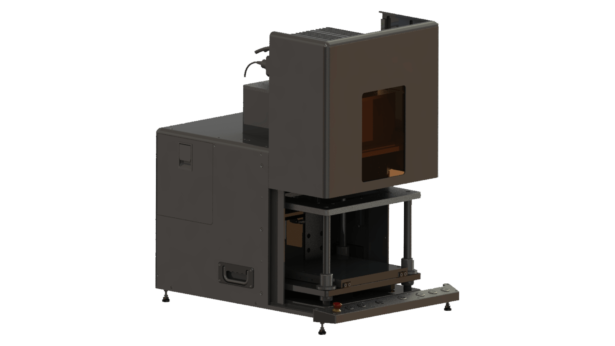

PWLM-Compact

Somack has developed a new laser-welding system. This laser-welding system is equipped with FAYb, the fibre-laser technology by Panasonic. This system ensures top quality welding results. The new laser-welding system makes plastic welding simple and hassle-free. The PWLM Compact main feature is its capability of creating weld seams of up to 200 mm x 200 mm on the components. And this on a defined space of 200 mm x 260 mm.

Laser-welding means that light is concentrated on a miniature focal point. The energy generated is extremely dense – the material to be welded melts within a blink. The seam cools down equally fast and becomes immensely strong immediately. This means that the component itself is not much stressed mechanically, and you obtain a clean welding seam from a reliable process which does not damage the machined component.

Laser-welding processes are mostly used for the joining of components requiring narrow welding seam shapes and low thermally-induced warping. The impressive benefits are: high welding speeds, excellent automation potential, and the option of an in-process Online quality inspection.

Our services

Your benefits at a glance

- High-quality laser-welding system

- Maximal reduction of set-up times

- Small footprint

- Integrated PC

Technical data

General data:

- Exterior housing dimensions (LxWxH): 600mmx543mmx810mm

- Weight: approx. 100 kg

- Cylinder stroke, Z-axis: 150 mm

- Cylinder compressive force: 1,000 N

- Door opening: Electrically-driven protective door

- Grid board: 200 mm x 260 mm

- PC: integrated, no-fan industrial PC

- Window: Viewing window 280mm x 200mm

- Welding range 200 mm x 200 mm

- Maximum component size: 200 mm x 260 mm x 130 mm

- Maximum component weight: 20 kg

Electrical connections

- Voltage: 230V AC

- Frequency: 50/60Hz

- Current: 10A

- Power consumption: 2.3kW

- Ambient temperature:

- Operation: 10-35°C

- Transport: 10-35°C