Milling

Job order production at Somack

Due to the high portion of in-house manufactured components in our products, we have a state-of-the-art and comprehensive range of machines for production. Because we manufacture high-technology machinery with very exacting components, we not only have the necessary technical equipment but also the requisite manufacturing expertise and highly-qualified personnel.

These resources are now here for you

The provision of capacities for job order production is an essential component of our component production unit. In addition to processing individual orders, we are also highly interested in long-term and sustainable collaborations.

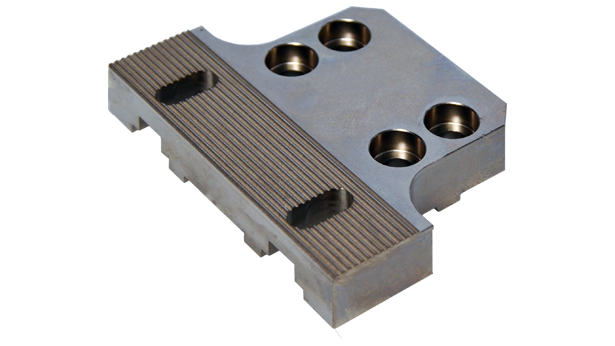

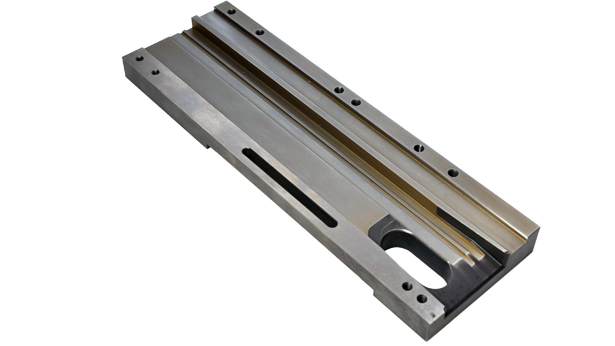

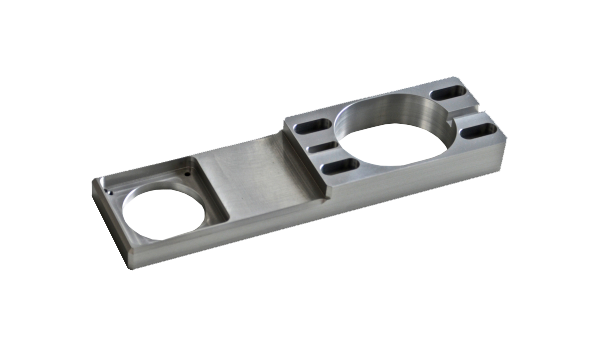

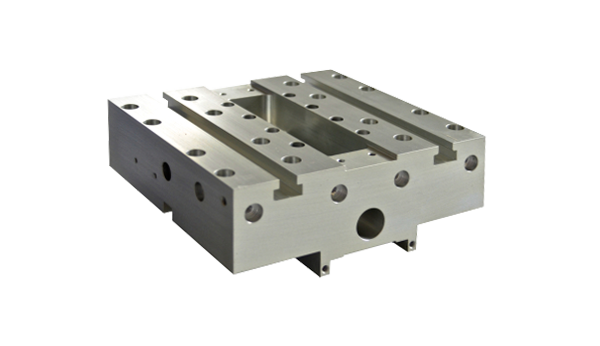

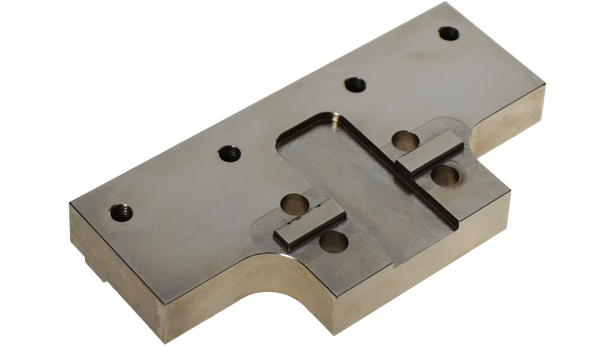

Panel processing

Our gantry milling machine allows us to manufacture your draft components up to dimensions of 3,750 x 1,750mm. Traversing paths (X/Y) : 3,750 x 1,750 (mm) Main spindle max. speed [rpm] [U/min] : 30.000 Main spindle max. [kW] : 14 Number of tool magazine slots [pieces] [Stück] : 245-Axis simultaneous milling

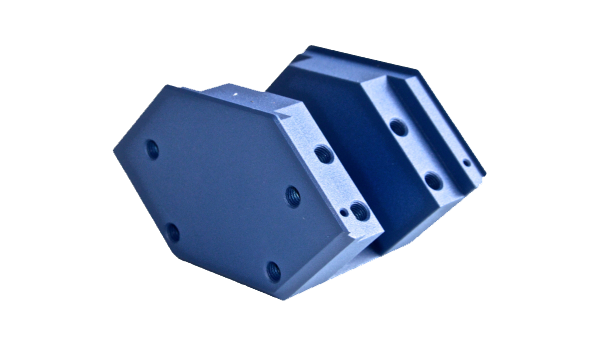

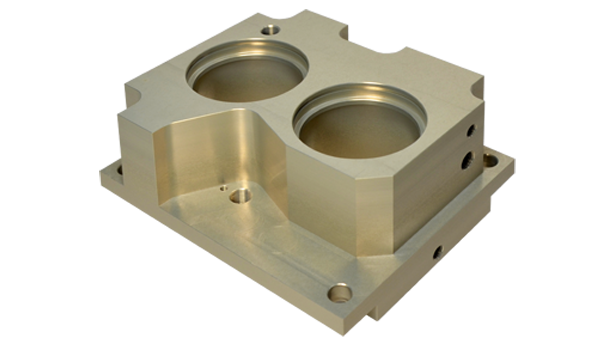

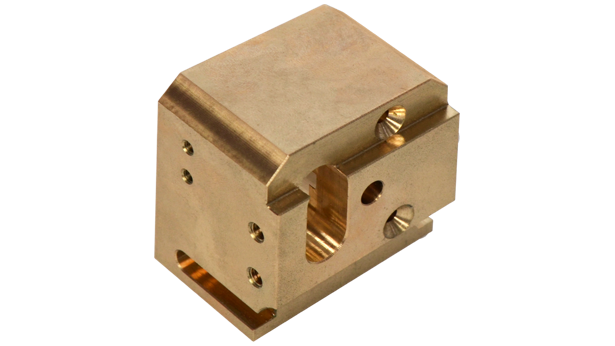

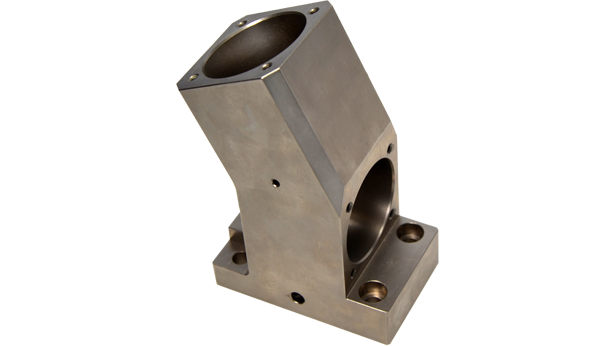

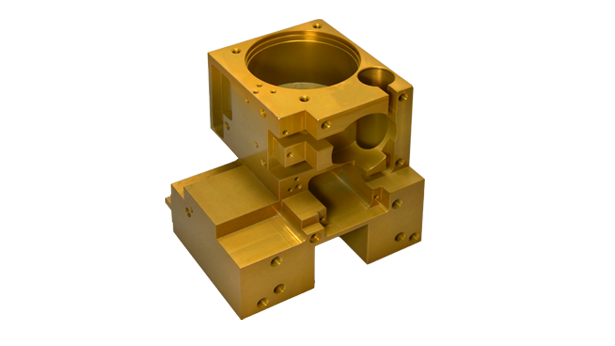

5-Axis milling has several advantages compared to standard 3-axis milling. At the one hand, it enables manufacturing of far more complex parts with, for example, cross bores and undercuts, which would require several re-clamping on a 3-axis machine. Hence, machining processes can be shortened considerably, tools with more stable properties may be used, and the surface qualities will be better. Your benefit: the reduced set-up and machining times save you money.